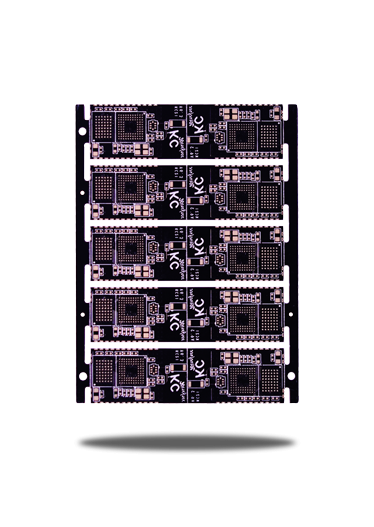

Multi-layer PCB

Our specialty is the production of multilayer PCB(40L), HDI PCB(2 steps), Special process & Special material PCB, such as Aluminum base PCB, Rigid-Flex PCB, High-Frequency PCB, Heavy Copper PCB ( 19OZ ), and so on.

Multi-layer PCB

Multilayer PCB Manufacturing

Multilayer PCB Manufacturing

The manufacture of high-layer, high-difficulty, special materials, special process circuit boards, which has always been our characteristics; the continuous improvement of high-multi-layer circuit board manufacturing process as our goal. Every year, we invest a lot of manpower and material resources in production equipment and process research and development, and strive to catch up with the development of cutting-edge circuit board manufacturing technology.

Multilayer Printed Circuit Board

We can produce up to 40 layers of high-layer circuit boards, various buried and blind vias circuit boards, and HID PCB. HDI PCB can be up to 2 steps.

High-difficult PCB

①: Min hole we can drill is 0.15mm, and 0.075mm for HDI design, and high-density print circuit board. ②: We can control impedance both single-end and differential for multi-layer(the min trace width/space is 4mil/4mil) ③: High precision circuit board( min trace width we can do 3mil, and the thinnest core we can do is 0.05mm) ④: Other special material board

Special Material

Heavy copper board( copper weight:210-700um), copper base material, aluminum, PI material, BT material, high-frequency material, Rogers Series, PTFE material, Taconic Series, Arlon.

Special Technology

①: Flex-rigid board, high to six layer flex in the inner layer, gold finger in flex area. ②: Steps boards: can expose the pad and circuit for inner circuit ③: Mixture surface treatment: OSP+ENIG ④: Multi-layer metal board: double side copper baseboard, double side aluminum board. ⑤: Mixture laminating: can process two or more material mixture laminating, like Ceramic +FR4+PTFE ⑥: Multi-frequency board: every board use high-frequency material ⑦: Plugging resin

-

Min hole we can drill is 0.15mm, and 0.075mm for HDI design, and high-density print circuit board.

-

We can control impedance both single-end and differential for multi-layer(the min trace width/space is 4mil/4mil)

-

High precision circuit board( min trace width we can do 3mil, and the thinnest core we can do is 0.05mm)

-

Other special material board

High-Quality Insurance

Ensuring quality during printed circuit board manufacturing is a continual process from start to finish.

①: We strictly train and test the operation for staff

②: The quality department will check every status for all the board, to ensure the board can meet the quality requirement.

③: Providing all test equipment( like AOI, fly probe machine and all kinds of test machine), so that can ensure and improve the quality checking.

The Application for Multi-layer PCB

From handheld portable electronic devices, to industrial machines and heavy equipment, communication devices and consumer electronics we see everywhere these PCBs. For example, Electronic consumption, Industrial manufacturing, LED lighting, electric power, Bluetooth communication, Radar antenna, aviation, automobile, and high-frequency communication.

Special Material for PCB

Normal FR4, high TG FR4, PTFE, ceramic, aluminum, metal base, flex material, BT, PI, and so on.

Special Process for PcB

We offer Special Process PCB, such as

• High Density PCB

• Annular Ring PCB

• Heavy Copper PCB

• Impedance Control PCB

• Rigid Flex PCB

• Buried & Blind Holes PCB

FR4+ceramic laminating

PTFE+FR4 laminating

heavy copper

flex-rigid

multi-layer